USA Pro.tect Black

Heavy duty black nitrile

Sold as a case of 10 boxes (100 gloves per box)

Code: P-GA004X

Product information

- Carbonite HD is our heaviest, thickest, strongest nitrile glove. Designed for durability, Carbonite HD is quickly becoming a favorite glove for the automotive and agricultural industries. Black color gives a professional look and is easily visible against most other colors.

-

Heavy duty nitrile is thick and strong to handle the toughest jobs

-

Finger-Tip finish provides excellent grip when handling wet or dry equipment

-

Powder free minimizes the risk of developing powder related allergies

-

Solid BLACK coloring making them perfect for many applications

Specifications

-

Sizes Available: S, M, L, XL

-

100 pcs per box, 10 boxes per case

-

Outer Case Dimension: 14 (L) x 10.5 (W) x 10 (H) in

-

Average Weight (Size M): 17 lbs

-

Medical Grade: No

-

Material: Nitrile (Synthetic Latex)

-

Length: 9.5"

-

Finger Thickness: 8 Mil average

-

Coating Process: Polymer Coated

-

Color: Black

-

Powder Free

-

Surface Texture: Finger Tip

|

EN ISO 374-1:2016+A1:2018 | EN374-4: 2019 (%) |

| Sodium hydroxide 40% (K) | 6 | -78.9 |

EN374-4 Degradation levels indicate the change in puncture resistance of the gloves after exposure to the challenge chemical.

| Level | 1 | 2 | 3 | 4 | 5 | 6 |

| Time | >10 | >30 | >60 | >120 | >240 | >480 |

This information does not reflect the actual duration of protection in the workplace and the differentiation between mixtures and pure chemicals. The chemical resistance has been assessed under laboratory conditions from samples taken from the palm only and relates only to the chemical tested. It can be different if the chemical is used in a mixture.

It is recommended to check that the gloves are suitable for the intended use because the conditions at the workplace may be different from the type test depending on temperature, abrasion and degradation. When used, protection gloves may provide less resistance to the dangerous chemical due to changes in physical properties. Movement, snagging, rubbing, degradation caused by the chemical contact etc. may reduce the actual use time significantly. For corrosive chemicals, degradation can be the most important factor to consider in selection of chemical resistant gloves.

Before usage, inspect the gloves for any defect or imperfections.

EN ISO 374-5:2016

| ✓ | ✓ | ✓ |

| Bacteria | Fungi | Virus |

The penetration resistance has been assessed under laboratory conditions and relates only to the tested specimen.

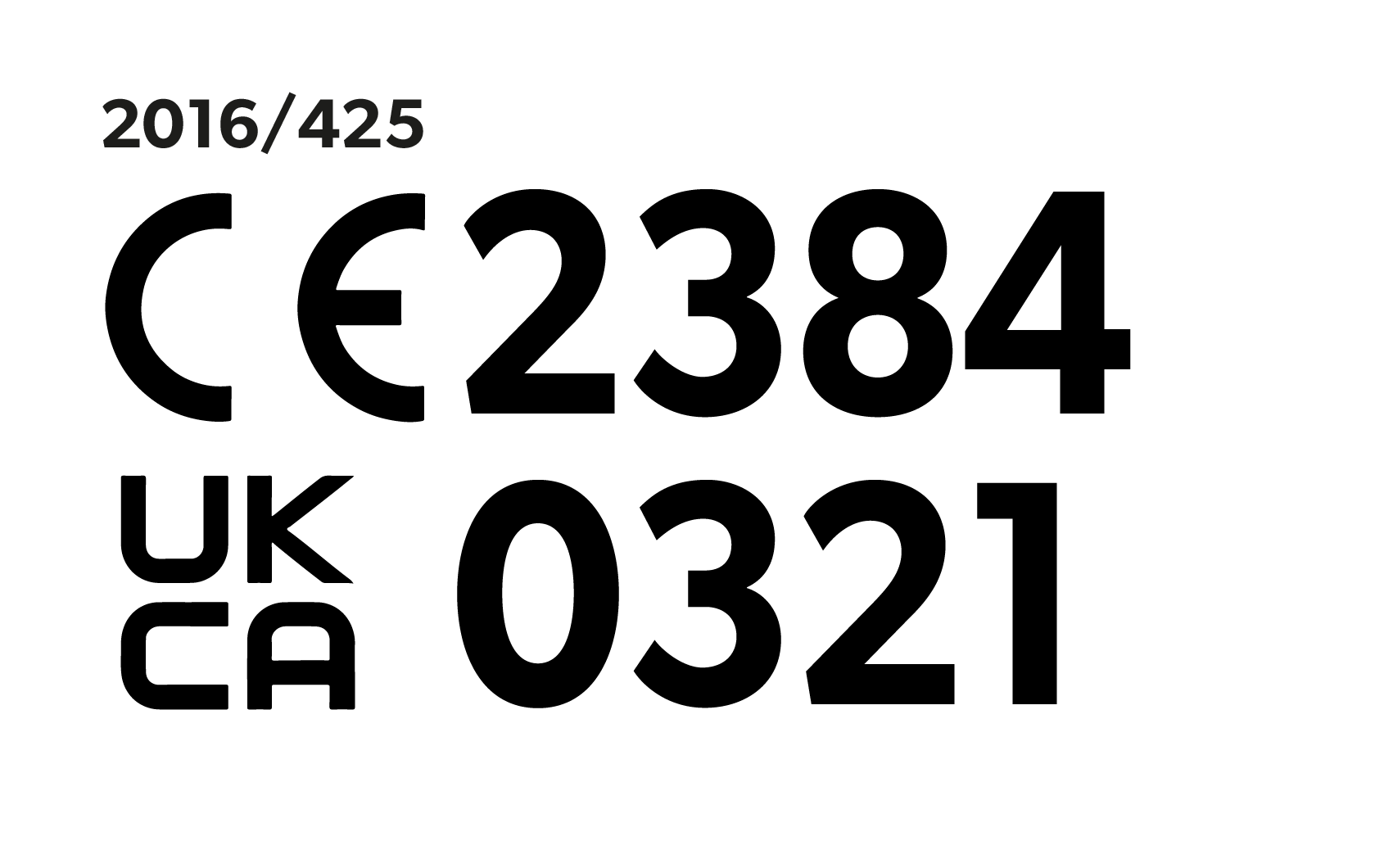

PPE certification (2016/425 Module B & Module C2) performed by:

CE: CCQS Certification Services Limited, Block 1 Blanchardstown Corporate Park, Ballycoolin Road, Blanchardstown, Dublin15, D15 AKK1, Ireland (Notified Body number 2834)

UKCA: SATRA Technology Centre Ltd, Wyndham Way, Telford Way, Kettering, Northamptonshire, NN16 8SD (Approved Body number: 0321)

Compliant with: Medical Devices Regulation (EU) 2017/745

Class I Medical Device

Other information

Contains accelerators which may cause allergic reactions.

|

Food safe |

|

Single use only |

|

Non-sterile |

|

Does not contain latex |

|

Store between 5 and 40 degrees Celsius |

|

Store in dry conditions |

|

Store away from direct sunlight and heat |

|

Packaging is recyclable |

| Size (Alpha) | Size (Numeric) | Code |

|---|---|---|

| S | 7 | GP0032 |

| M | 8 | GP0033 |

| L | 9 | GP0034 |

| XL | 10 | GP0035 |

For more information please see the Warehouse Data Sheet.